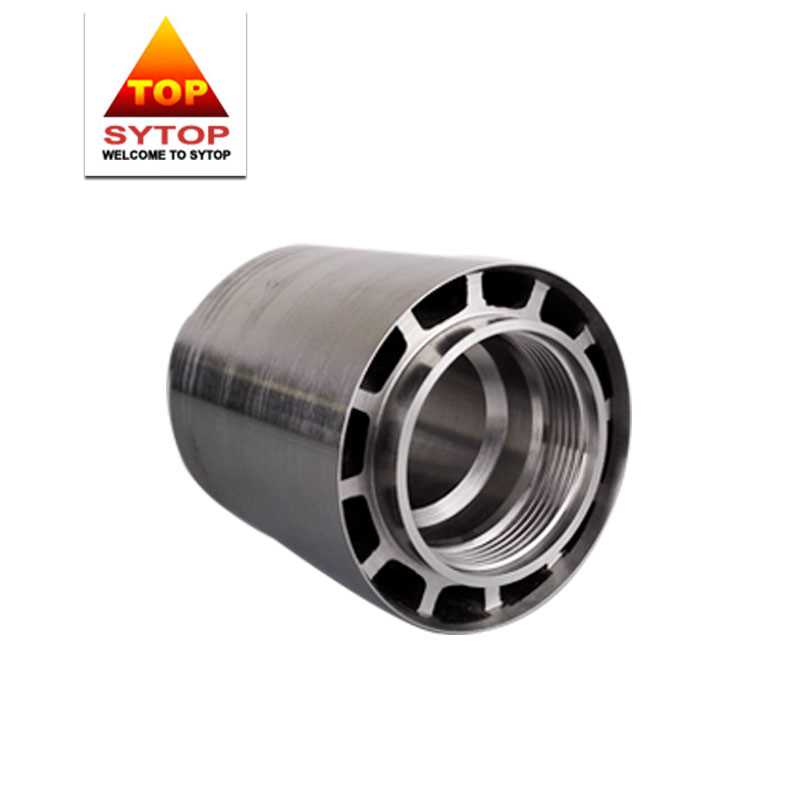

Materials of rotor and stator--Cobalt Chrome Stellite Alloy

---Excellent wear and corrosion resistance even at high temperature up to 800℃

SYTOP cobalt base alloys is a range of cobalt-chromium-tungsten alloys with wear resistance, corrosion and high thermal resistance. It is widely used in oil & gas, machinery, wood cutting, automotive, paper and food processing industry etc.

bucket bushing stellite 6 metal bushing metal sleeve bushing motor rotor stator nozzle dental metal alloy impeller liaoning

Chemical compositions and properties (%)

|

Brand

|

C

|

Mn

|

Si

|

Cr

|

Ni

|

Mo

|

W

|

Co

|

Fe

|

P

|

S

|

Density

(g/cm3)

|

Hardness

(HRC)

|

|

TOPS 3

|

2.0-2.7

|

1.0

|

1.0

|

29-33

|

3.0

|

|

11-14

|

Bal.

|

3.0

|

≤0.03

|

≤0.03

|

8.55

|

51-55

|

|

TOPS 6

|

0.9-1.4

|

1.0

|

1.5

|

27-31

|

3.0

|

1.5

|

3.5-5.5

|

Bal.

|

3.0

|

≤0.03

|

≤0.03

|

8.35

|

38-44

|

|

TOPS 12

|

1.1-1.7

|

1.0

|

1.0

|

28-32

|

3.0

|

|

7.0-9.5

|

Bal.

|

3.0

|

≤0.03

|

≤0.03

|

8.40

|

44-49

|

|

TOPS 20

|

2.2-3.0

|

|

2.0

|

30-34

|

3.0

|

1.0

|

14-18

|

Bal.

|

3.0

|

≤0.05

|

≤0.05

|

8.65

|

53-59

|

|

TTG 25

|

2.2-2.8

|

1-3

|

|

27-32

|

7

|

Ta/Nb

|

14-19

|

Bal.

|

2-5

|

|

|

8.84

|

57-60

|

|

TTG 35

|

3.3-3.8

|

1-3

|

|

27-32

|

7

|

Ta/Nb

|

14-19

|

Bal.

|

2-5

|

|

|

8.80

|

60-63

|

|

T400

|

0.04

|

|

2.5-2.7

|

8-10

|

|

27-29

|

|

Bal.

|

|

|

|

|

55

|

|

T800

|

0.04

|

|

3.2-3.6

|

16-18

|

|

27-29

|

|

Bal.

|

|

|

|

|

58

|

Q1: Are you a manufacturer or a trading company?

A1: We are the manufacturer located in the north of China with 15 years producing experience and 10 years exporting experience.

Q2: What's the material of your valve seats?

A2: It's the CoCrW alloy, which is usually called stellite alloy.

Q3: What's the stellite alloy?

A3: It is a range of cobalt-chromium alloys designed for wear resistance, heat

resistance and corrosion resistance.

Q4: What's the production process of your rotor and stator?

A4: It's by investment casting process and HIP treatment.

Q5: What's the lead time of your rotor and stator?

A4: 30 days depending on the order quantity. Immediate delivery with standard stocks.

Q6: What's the tolerance and surface finish we can control?

A6: As your demand.

Q7: How do we deliver the rotor and stator?

A7: Air or sea way. We are the VIP customer of DHL express, having good discounts.

Q8: MOQ?

A8: 1pc

Q9: Why I choose your company?

A9: We are professional. We are reliable. We are easy communication.

Your feedback is our best honor, please do not hesitate to give us your valuable feedback.

Shenyang Top New Material Co., Ltd.

Basic Information

Business Type:Manufacturer, Trading Company

Main Products:Cobalt Base Alloy Tungsten Base Alloy Sliver Tungsten Alloy Copper Tungsten Alloy Nickel Base Alloy Cermet

Location:No. 35, Xingnong Road, Shenbei New District, Shenyang, Liaoning, China

Total Employees: 54

Year Established: 2001

Trade Information

Top 3 Markets:

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF

Nearest Port: Dalian

Average Lead Time:30

Overseas Office: No

Company Pictures

Verified Supplier

Credit Check