The LH series homogenizer is the new product developed by our company based on the up-to-date International technology of 1990 s.

The equipments is used to homogenize, emulsify, spray and high pressure transport liquid

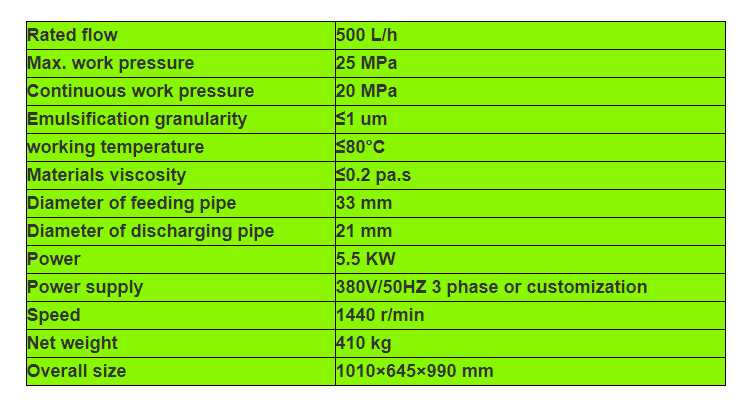

Materials whose viscosity is less than 0.2 p.as, temperature is lower than 80 c (liquid-liquid

Phase or liquid-solid phase).

In working, with the advance and return movement of plunger piston, open and close of rebound

Valve and covered core inside the pump, to control the slight clearance between the valve head and valve base inside the adjusting valve effectively, so form strong high pressure energy.

The materials could fulfill the purpose of homogenization and emulsification under the instant action of combined force of turbulent flow, cutting, collision and cavity.

The equipment is widely used in the production, scientific research and technical development of a lot of areas, such as: food, dairy food, drink, pharmacy, chemical industry, biological technology and so on.

1, Be used as high pressure homogenizer It can cause the material homogeneity and mixture under the three action of extruding, strong impacting and decompression inflating. It is an important equipment of food, dairy food, drink processing and so on. It can cause the fat globule thinning while homogenating under the high pressure to the milk, soy milk this kind of dairy food. And cause its products to be easy to digest and absorb, and to improve the dietary value. It can improve the fineness and the fraction void of the fluid material, as well as its intrinsic quality, while be used in the processing of ice cream this kind of production. If be used in the producing of emulsion, glue, fruit juice, syrup and so on, it will prevent or reduce the delamination of the material, improve the appearance of the material, and make the luster more bright, the fragrant thicker and tasting mellower.

2, Be used as high pressure delivery pump

It is an important equipment during the production of powdered medicine, as the fluid material produce high pressure when through the equipment, and be made to powder after through the spray drying device.

This equipment also can be used in the emulsification, high-pressure transportation and the high pressure spray situation of other fluid materials.

—Feature—

1. It is composed of frame, wheel box, pump body, pressure meter and homogenizer and so on.

Its designs is reasonable and original, variety is ample. As follows:

Special model for sterilized milk.

Special model for fruit juice and beverage.

Special model for alcoholic liquor.

Special model for albumen drink.

Special model for cold food (thick plasm).

Special model for lubricating grease.

Special model for chemical industry.

Special model for condiment( sauce, vinegar, and so on)

Special model for special purpose

2.The outside and main parts adopt high quality stainless steel and corrosion resistant alloy,

So it useful time is longer, its outside is very exquisite, meet the food sanitation standard.

3.Pressure control adopts two-tier mechanical pressure regulating, it is easy to regulate, safe And reliable.

4.The plunger piston adopts some new material of wearproof alloy spray alloy and china,With the characteristics of anti-corrosion, wearproof.

The high pressure sealing of plunger piston adopts self-caulking gasket ring, V-shape Gasket ring, combined type gasket ring, with long useful time.

5.Bent axle drive adopts one-stage drive mode, with stable running, small power loss, and low noise.

MEC Ice Cream

Basic Information

Business Type:Trading Company

Main Products:Ice cream pre-treatment machine,Ice cream moulds machines,Ice cream extrusion machines,Ice cream filling machines,New type ice cream machines,Ice cream sugar cone machine

Location:

Total Employees: 51 - 100 People

Year Established: 1997

Trade Information

Top 3 Markets:

Accepted Payment Currency:USD,EUR

Nearest Port: Shanghai

Average Lead Time:65

Overseas Office: No

Company Pictures

Verified Supplier

Credit Check