ABOUT US:

Wuxi Jinkun Machinery Manufacturing Co. LTD is located in Wuxi city, which is 150 kilometers away from Shanghai.

The company is mainly focus on producing and selling machines for aluminum collapsible tubes line, aluminum aerosol cans line and toothpaste line. The company has taken part in this field for 30 years. The standard of conduct is to provide better products and service for our clients. We also provide professional consultation and service for clients.

Aluminum collapsible tubes line includes extrusion press machine, trimming machine, annealing oven, internal coating machine, lacquer curing oven, accumulator, base-coating machine, 4-color printing machine, 5-color printing machine, 6-color printing machine, drying oven, latexing machine and capping machine.

Aluminum aerosol cans line includes extrusion press machine, trimming machine, washing machine, accumulator, internal coating machine, lacquer curing oven, base-coating machine, varnish machine, 6-color printing machine, 8-color printing machine, drying oven and necking machine.

The machines are widely used to product aluminum collapsible tubes, aluminum aerosol cans or bottles, toothpaste and pack other paste products. Our company has independent import and export right. Our machines has been exported to 30 countries and regions like France, Spain,Turkey, Argentina, India, Pakistan,Bangladesh, Burma, Vietnam, Malaysia, Thailand, Indonesia, Syria, Saudi Arabia, Egypt, Asia, Mexico, Peru, Algeria and Nigeria etc. Our machines are deeply welcomed by customers.

‘Create value for clients by professional service’ is our forever company tenet. We are looking forward to cooperating with friends from different countries and creating the brilliancy together.

PRODUCT:

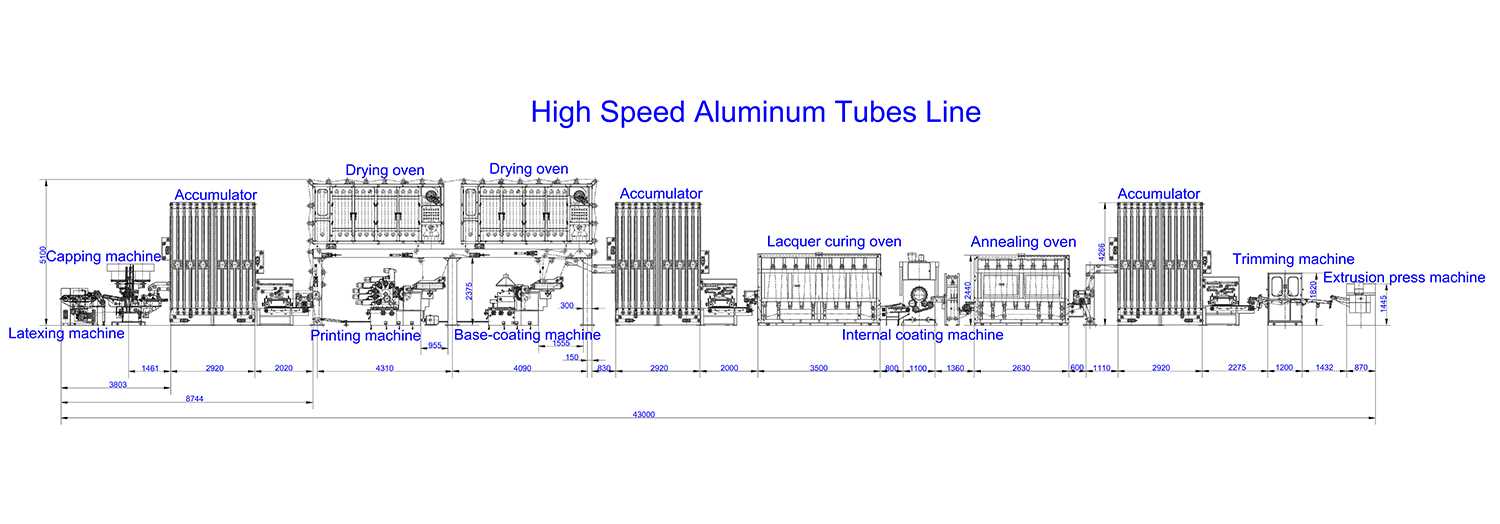

1.High Speed Aluminum Tubes Line

Product Application

Aluminum soft tubes line or collapsible tubes line is a set of machines to produce tubes to pack products like ointment, artistic pigment, cosmetics, sealant, toothpaste, shoe polish, AB glue, hair dye, tomato sauce, chocolate sauce, instant adhesive, pen barrel, cigar, etc.

The JK series aluminum tubes lines produced by us are fully automatic. Each equipment of the series can work alone or form an automatic production line partially or fully, according to client’s needs. The machines include JK01 Extrusion press,JK02 Trimming , JK03 Annealing oven, JK05 Internal lacquering machine, JK06 Lacquering curing oven, JK07 Accumulator, JK08 Base-coating machine, JK09 6-color andJK09A 8-color printing machine, JK12 Drying oven, JK14 Capping machine, JK15 Latexing machine andJK16 Packaging machine.

All the equipment of the series is properly aligned in structure, advanced in design, highly automated and fast in production. All devices adopt SIEMENS PLC to ensure stability and all ovens employ FUJI Temperature Controller to automatically control the working temperature.

Main units and controlling components all adopt branded products to ensure reliable and stable working performance. All the products can be passed automatically through the production line. The color touch screen can display the instant information of speed and production, making it convenient for management.

SPECIFICATIONS FOR High Speed Aluminum tube line

| Production speed |

≤120pieces/min |

| Diameter |

φ16mm- φ25mmor φ25mm-φ35mm |

| Motor power |

230KW |

| Dimensions |

45000×4200×5300mm |

| Intake pressure |

0.55MPA |

| Gas consumption |

335M^3/24h |

| LPG consumption |

200~335kg/24h |

Main Features

1) PLC: SIEMENS

2) Touch screen: Pro-face

3) Pneumatic element:FESTO

4) Terminal display:SIEMENS

5) Bearing:NSK or NTN

6) Approach switch:BANNER

7) Photo switch:TURCK

8) Divider:TANTZU

9) Electrical component:SCHNEIDER or OMRON

Main Machine

1.Name: JK01-80 Extrusion press machine

Application and operating principle:

Horizontal extruder is also called horizontal extrusion press machine. This is a specialized equipment which extrudes aluminum and other non-ferrous slugs into germ tubes or cylindrical objects and other shapes.The JK01-80 extrusion press machine developed by our company, is a high speed aluminum extrusion device of new generation. This equipment comes with vibratory bowl which automatically arrange the aluminum slugs in order and send them to the laying-off rail. The machine manipulator sends the slugs precisely into the punch cavity. Under the action of the crank-shaft connecting rod, swing rod and sliding block, the aluminum slugs are extruded in desired shape and size.

The clearance between body of punch and die controls pipe thickness. Through the annular slot between the carbide ring and tip of punch, the slugs are pressed and turned into germ tubes, the extruded part is automatically unloaded to the out feed conveyor which transfers the product to next operation stage.

Main technical parameters

A. Nominal pressure: 800kN

B. Tube diameter range: φ13.5mm-φ27mm

C. Tube

Wuxi Jinkun Machinery Manufacturing Co. LTD

Basic Information

Business Type:Manufacturer

Main Products:High speed aluminum tube line

Location:

Total Employees:

Year Established:

Trade Information

Top 3 Markets:

Accepted Payment Currency:false

Nearest Port:

Average Lead Time:60

Overseas Office: No

Company Pictures

Verified Supplier

Credit Check